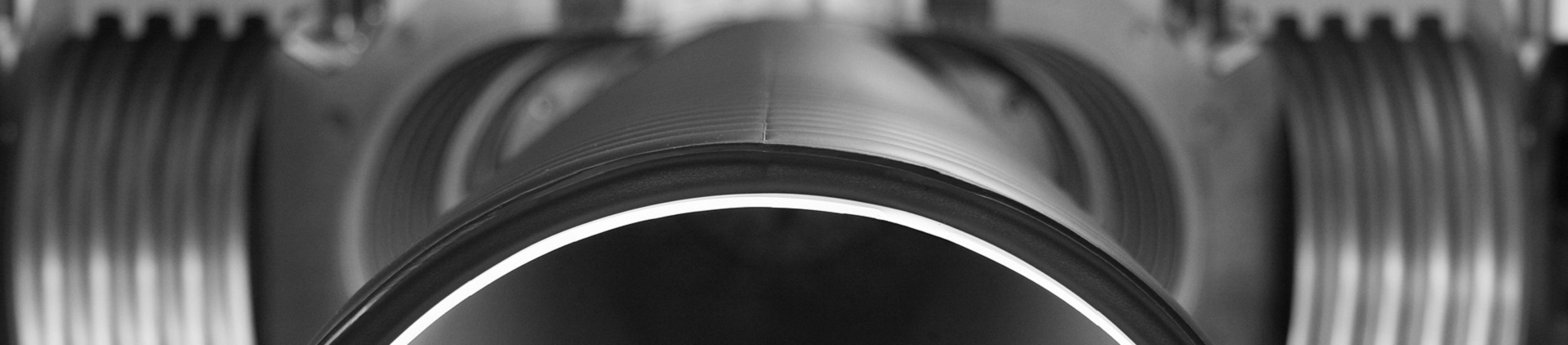

Corrugated pipe systems

Machine series

- Inovo

- Avero

- Protos

Maintools TSK Corrugators for corrugated and composite pipes from 4.5 mm to 500 mm are very varied and specially developed for the requirements and concerns of everyday production.

Features

Inovo corrugated tubes from 4.5 mm to 25/54/60 mm

- modular construction

- complex control options

- High-performance models

- simple operator guidance

- Remote maintenance module in standard scope

- low-maintenance operation

- special curve geometries

- special control and warning functions

Model variant Speedy

- low-wear mold jaw circulation by second drive in the return line

- Production capacity 50 m / min (polyolefins) 65 - 70 m / min (PVC)

Protos corrugated tubes from 40 mm to 305 mm

- For demanding tasks and applications

- Maintenance-free cooling system with hight water flow

- Fast mold jaw change

- Multiple mold jaws

- Automatic compensation of the shape jaw clearance

- maintenance-free cooling system

- Different vacuum zones with variable positioning

- Control with touch screen and remote diagnostics

- Split center channel with quick opening function and "zoom technology"

- Weight-reduced shape jaws

- Short tool lengths

- Higher throughput

Avero corrugated pipes from 150 mm to 1200 mm

- Zoomability of the mold jaws

- High mechanical speed up to 8 m/min

- Advantages of cooling are identical to the Protos series: no couplings, hoses, etc., mold jaws are cooled during the complete cycle (not with a shuttle construction)

- Production of an inline sleeve possible

- Symmetrical vacuum system

- Compact design

- More energy efficient in the competition comparison

- hydraulic corrugator slide

- Absolutely trouble-free and reliable operation in case of power failure

- Low maintenance operation

- compact design

- no additional USV or UPS necessary

info@maintools.de

info@maintools.de