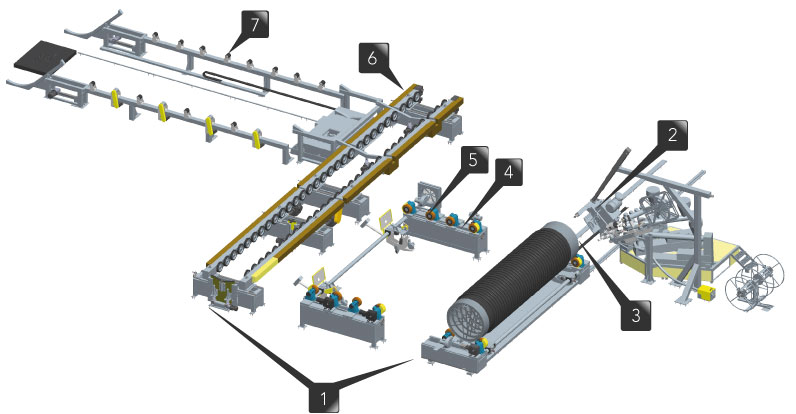

Spiral winding line

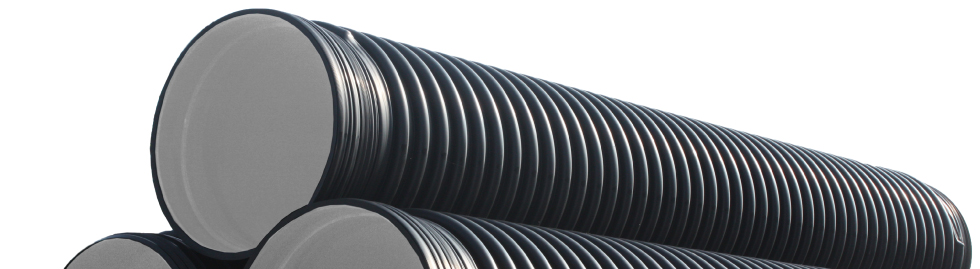

Maintools TSK winding tube technology: Production of winding tubes in the diameter range 300mm to 4300mm in accordance with international standards DIN 16961, ASTM F-894 and EN 13476, in stiffness classes up to SN 16 according to DIN EN ISO 9969. machine seriesMachine series

Machine series for the production of winding tubes with nominal widths up to 2400 mm and 4300mm.

Maintools TSK winding tube technology: Production of winding tubes in the diameter range 300mm to 4300mm in accordance with international standards DIN 16961, ASTM F-894 and EN 13476, in stiffness classes up to SN 16 according to DIN EN ISO 9969.

Produktdetails

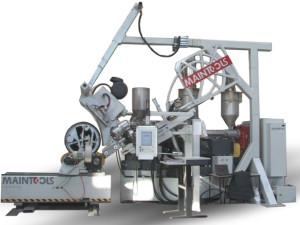

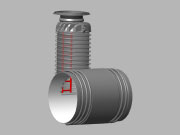

works picture TITAN mandrels (blanks) Welding sleeve

Welding sleeve

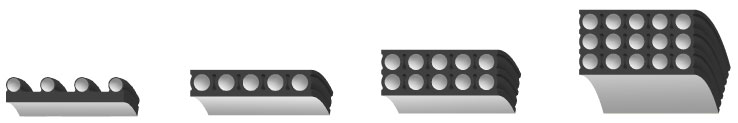

Profile example

Functional principle of the machine

- Step 1

Transport of the drum from the demoulding to the winding station. - Step 2

Heating the drum - Step 3

Winding the tube - Step 4

Cooling the raw on the drum - Step 5

External machining of the pipe and cooling - Step 6

Final shaping of the tube - Step 7

Quality control and manual work

Advantages

- Increased product stiffness with low material usage

- Highest degree of operating comfort through intuitive process control

- High energy efficiency

- Low operating costs

- Future-oriented burner technology

- Variable product lengths

- High product flexibility in profile design

- In-line sleeves possible

- Processing of PE and PP

- Maximum production reliability

- Production of fittings and manholes possible

Application areas

- Silo and cistern construction

- ventilation ducts

- Penstocks

- Tank and wastewater technology

- Sewer and sewage technology

- Industrial custom-made products

- United drainage systems

- Drinking water storage and piping systems

info@maintools.de

info@maintools.de