Maintools TSK Machinery corrugators offer all the advantages required for modern plastic pipe production: maximum precision, efficiency, and durability. Advanced control systems and innovative technology ensure consistent quality and reliable processing of a wide variety of materials. The energy-efficient components not only contribute to cost savings but also to environmentally friendly production. The machines are specially designed to optimize production processes and minimize downtime. This enables continuous and economical production that delivers consistently high performance even under demanding conditions. Our corrugators combine state-of-the-art technology and robust design and meet the high requirements for precision and efficiency in corrugated pipe production.

The INOVO series sets new standards in corrugated pipe production and combines efficiency with maximum precision up to a diameter of 60 mm.

Our innovative corrugators offer impressive production speeds without compromising on quality.

Thanks to energy-efficient components, the INOVO series significantly reduces resource consumption and thus also lowers operating costs.

The machines can be flexibly adapted to different product requirements and easily adjusted to individual production needs.

With a user-friendly touchscreen and freely programmable speed control, the INOVO series ensures intuitive operation and maximum operational reliability.

All machine parameters can be displayed graphically and transferred to external storage media. With our INOVOs, the highest product requirements and consistent process capability can be achieved.

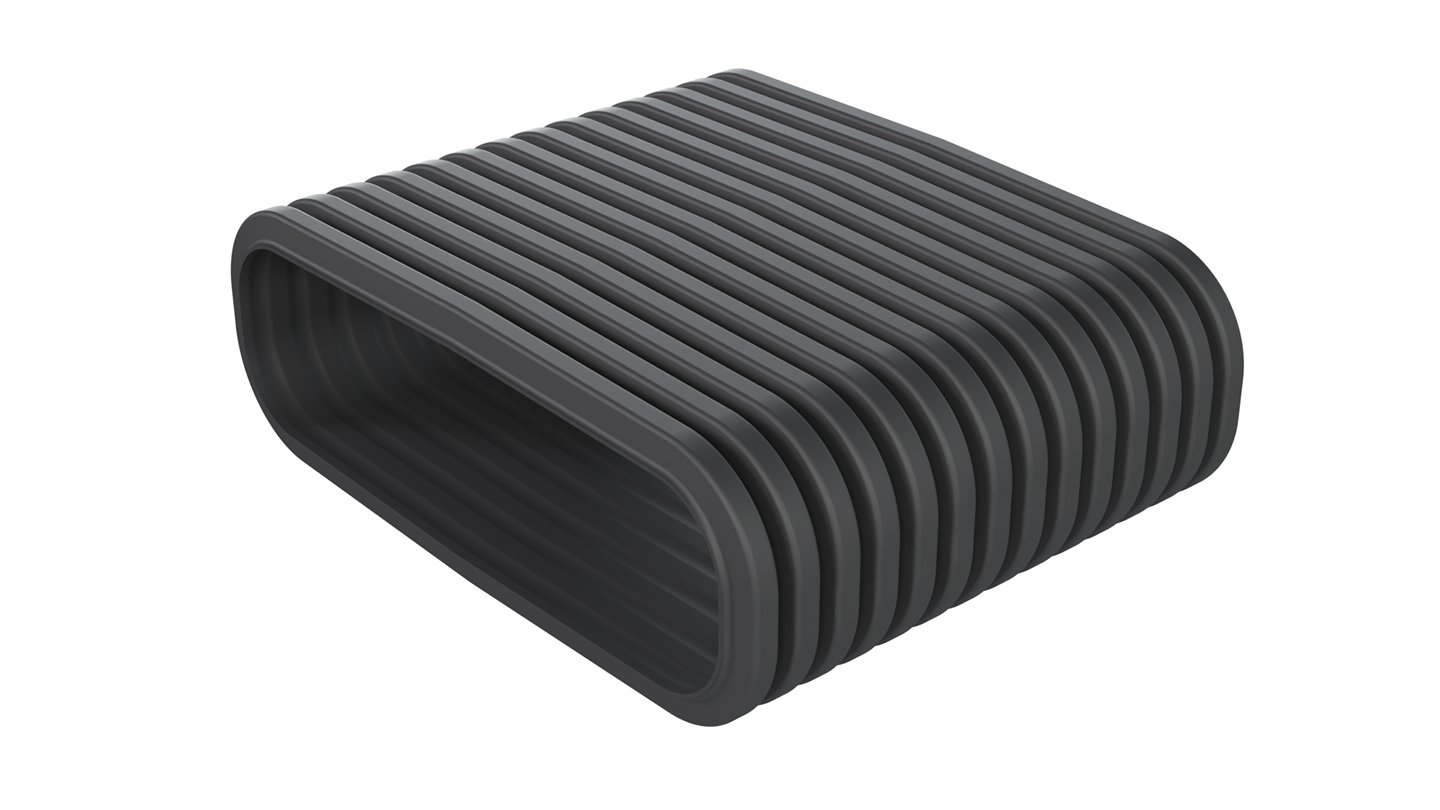

Stainless steel spiral vacuum hoses complement our robust systems.

This means that our systems are not only optimized for today’s requirements, but also perfectly equipped for the challenges of the future

Our SMALL model. Ideal for small dimensions up to 15 mm. Variable in terms of number of forming jaws and product geometry.

This versatile machine offers high speeds and efficiency for the production of standard corrugated pipes up to 18 mm.

Our HIGHSPEED. Perfect for technical products in combination with high speeds. The system offers maximum flexibility in terms of the number of mold blocks. Perfect ratio of maximum product diameter to mold block length. For further details, please refer to the technical data sheet.

Our standard vacuum corrugator up to 54 mm. Perfect for technical products due to the high variability of the number of forming jaws. Our symmetrical vacuum system offers maximum vacuum performance up to the forming jaw profile. A freely programmable speed control is standard. Spiral vacuum hoses made of stainless steel complement the robust system.

Our HIGHSPEED for diameters up to 54 mm. Perfect for technical products in combination with high speeds. The system offers maximum flexibility in terms of the number of forming jaws. All technical features of the INOVO54 / 42-82 VE are also standard on the INOVO54 XL. For further details, please refer to the technical data sheet.

The PROTOS series was developed specifically for the production of larger corrugated pipes and impresses with its high performance and robustness. Our PROTOS corrugators offer exceptional flexibility and can handle even the most demanding material requirements with ease. The PROTOS series enables high production speeds while guaranteeing precise quality. With its stable construction, divisible center channel, and energy-efficient technology, the PROTOS series ensures cost-optimized production with minimal resource consumption. Our sleeveless and maintenance-free mold block cooling, in conjunction with our quick-change system, guarantees short downtimes when changing dimensions. Each mold block is supplied with cooling water separately, which guarantees the most uniform mold block temperatures possible.

Optimized vacuum technology enables the production of technical products with high precision. The hydraulic operation of the corrugator in conjunction with a pressure accumulator prevents damage to the system in the event of supply fluctuations.

The user-friendly controls and the ability to adapt to specific production requirements make our PROTOS the ideal choice for companies that work with larger dimensions and demand efficiency and reliability. Corrugated pipes are used in drainage, cable protection, sewage, and ventilation pipes. Complex geometries such as oval ventilation pipes, pipes with smooth sections, etc. can also be produced on the systems.

Our basic system for diameters up to 165 mm, equipped with 40 pairs of mold blocks. Two energy-optimized drives, supplemented with all the features of the PROTOS series.

The powerful system with 60 pairs of molding blocks is suitable for high production speeds in the diameter range from 32 to 165 mm. Four energy-optimized drives for the molding block circulation ensure minimal wear and maintenance.