Our caterpillar extractors, specially designed for corrugated pipes, are available as stand-alone versions or integrated into the cooling spray bath.

Optionally equipped with servo motors, the caterpillar extractors operate reliably and synchronized with the corrugator, suitable for corrugated pipes from 4.5 mm to 305 mm OD.

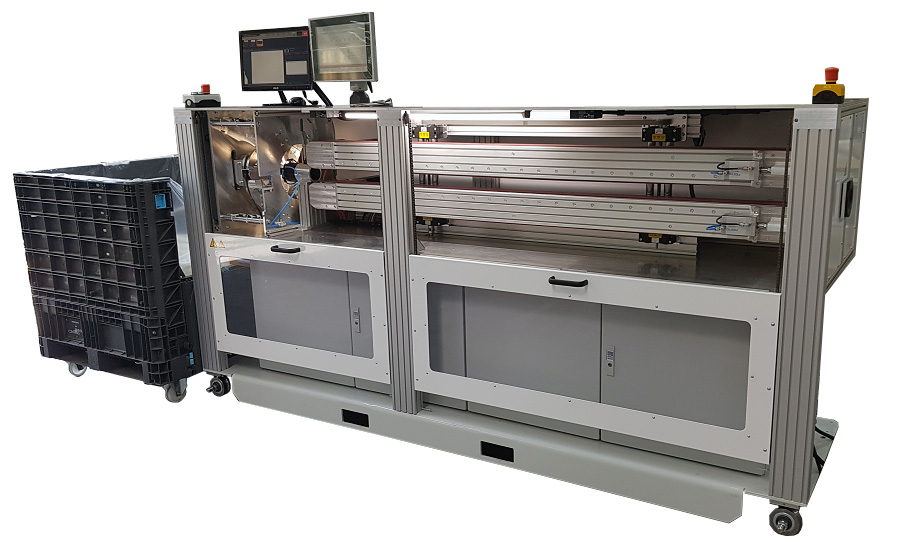

Our cooling spray baths are primarily ordered by our customers integrated with a caterpillar conveyor. Advantage: One control cabinet for two compact downstream units. Further integration with a spark tester has also been carried out many times. In addition, MAINTOOLS TSK machinery cooling spray baths have an efficient raw material drying area. The cooling section can be customized in increments of 1.5 to 4 meters according to customer requirements. Eccentric hollow cone nozzles cool the extruded corrugated pipe with a nominal diameter of 4.5 to 305 mm all around.

We offer rotary cutters with a production speed of approx. 60 m/min, which are specially designed for cutting technical pipes in the automotive sector. The cutter is monitored by camera and the products can be stored in a database and retrieved as required. Sorting and storage tables complement the cutter.

Spark testers from Zumbach are used to detect leaks in corrugated pipes. A wire previously inserted via the spray head is kept under tension inside the corrugated pipe and serves as a counterpole. The spark tester applies all-round voltage to the pipe via copper brushes. If there is a pinhole-sized hole, the voltage passes through to the wire and a warning signal is triggered.

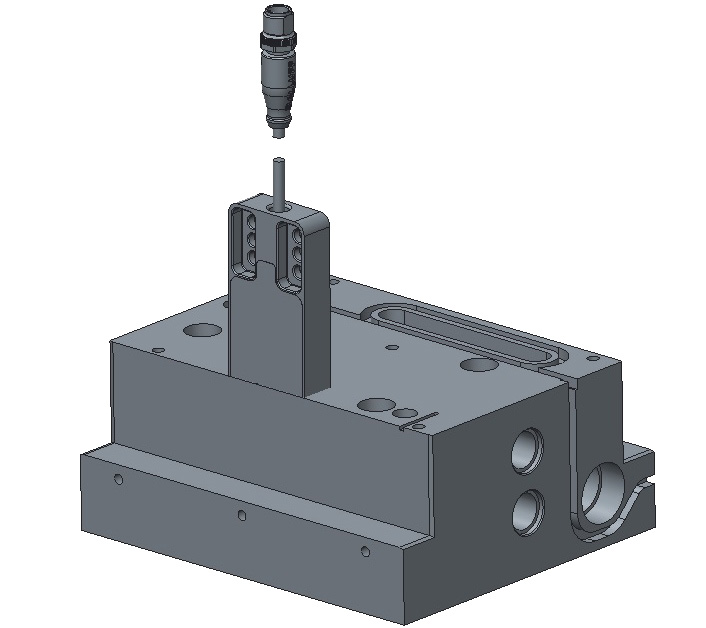

In order to check the correct sequence of the mold blocks installed in the corrugator’s carriage before start-up, the mold blocks are each equipped with an RFID chip. An RFID transponder installed in one of the modules reads the mold blocks in the chain and checks the sequence according to predefined recipes based on the product drawings.